kp Klearcup®

Lightweight dairy applications you can customise

kp Klearcup®polystyrene provides significant benefits and still meets performance needs by foaming the core of the film. With a 30% improvement in natural polystyrene and a 25% reduction in haze versus natural polystyrene, kp Klearcup® wants to make your product stand out on the shelf.

Packer/processor benefits

- Crush strength keeps the product safe in transit

- Moisture and oxygen transmission is ideal for live cultured dairy products

- Drop-in settings for form, fill, seal and cut

- Meets top load requirements of standard polystyrene (PS) cups

- Fully snappable films for multi-packs

Retailer benefits

- Various colour options available

- 90% improvement in transparency

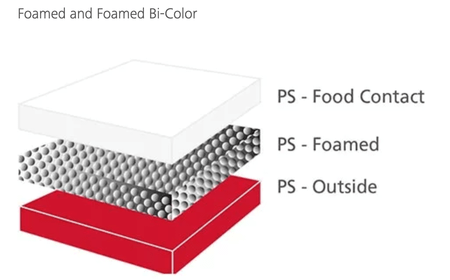

- Four layers available to customise appearance

- High gloss finish available

Sustainability

- Reduces food waste

- Transport-efficient, resulting in less greenhouse gas emissions and less post-consumer solid waste

Technical information

- 30% improvement in clarity over natural polystyrene

- 25% reduction in haze vs natural polystyrene