Pharmaceutical films: Barrier breakthroughs protecting medicines and patients

In the pharmaceutical industry, packaging serves as a critical component in ensuring drug efficacy and patient safety. Medications are susceptible to environmental factors such as moisture, oxygen, and light, which can compromise their potency, reduce shelf life, and pose risks to patients. High-barrier pharmaceutical films act as an invisible shield, protecting medicines from these external threats.

Barrier films are carefully engineered to create optimal protective environments for pharmaceuticals. They prevent degradation caused by external elements by employing advanced material science, combining layers of specialised polymers and coatings. This ensures that medications remain stable and effective throughout their intended shelf life.

As pharmaceutical formulations become more complex, packaging solutions must evolve accordingly. Klöckner Pentaplast (kp) leads the way with innovative high-barrier films tailored to specific drug protection needs:

As pharmaceutical formulations become more complex, packaging solutions must evolve accordingly. Klöckner Pentaplast (kp) leads the way with innovative high-barrier films tailored to specific drug protection needs:

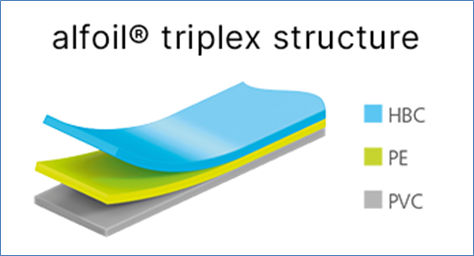

alfoil®: A high-performance line of PVdC-coated films offering mid-to-high barrier protection against moisture, oxygen, and aroma. Available in various coat weights and structures, alfoil® films are cost-effective solutions for most hygroscopic and oxygen-sensitive pharmaceuticals.

Aclar®: These multi-layer laminate films are highly transparent and clear, offering excellent thermal stability and chemical inertness. They provide best-in-class moisture barrier protection and can be processed using standard equipment and tooling.

kpNext® RB5: Designed with recyclability in mind, kpNext® RB5 is a sustainable high-barrier option. These vinyl-free and halogen-free barrier films have the same thermoforming functionality as traditional packaging materials, aligning with circular economy goals while maintaining barrier integrity.

The appropriate packaging ensures that medicines remain effective from manufacturing to administration. High-barrier films play a crucial role in safeguarding treatments for chronic diseases, temperature-sensitive biologics, and life-saving drugs. Beyond protection, sustainability is shaping the future of pharmaceutical films. kp leads the charge with kpNext® RB5, demonstrating that high-barrier protection and environmental responsibility can coexist.

Advancements in pharmaceutical films continue to redefine possibilities, balancing performance, patient safety, and sustainability. As regulatory demands grow and drug formulations become more specialised, innovative barrier films will remain key enablers of modern medicine.

At kp, we are committed to driving these breakthroughs, with plans to expand our kpNext® family by introducing new recyclable, high-barrier solutions that integrate seamlessly into existing manufacturing processes.

These forthcoming innovations aim to provide superior moisture protection and chemical resistance, further aligning with our sustainability goals and supporting a circular economy. By continually advancing our product offerings, we ensure that pharmaceutical packaging evolves in step with the medicines it safeguards.

More like this